This week’s special guest author is Vladimir Romanov . Vlad, a problem-solver at heart, built his first circuit at 12, programmed in C++ by 14, and pursued Electrical engineering as a career. With experience leading multimillion-dollar projects at P&G, managing operations at Kraft Heinz, and driving digital transformation as a consultant at DreamVersion, his is now expanding his expertise with an MBA at McGill, focusing on Business Strategy and Finance.

Introduction to IT / OT in Manufacturing

Over the years, I’ve had countless conversations with both IT and OT professionals in manufacturing, and one thing is clear—these two groups rarely see eye to eye. I’ve been in the middle of this struggle, working on the plant floor with automation engineers, electricians, and technicians, while also sitting in meetings with IT teams discussing cybersecurity policies, data governance, and enterprise networks. The divide between these two worlds is real, and it’s not just a minor disagreement—it’s a fundamental clash of priorities, cultures, and ways of working.

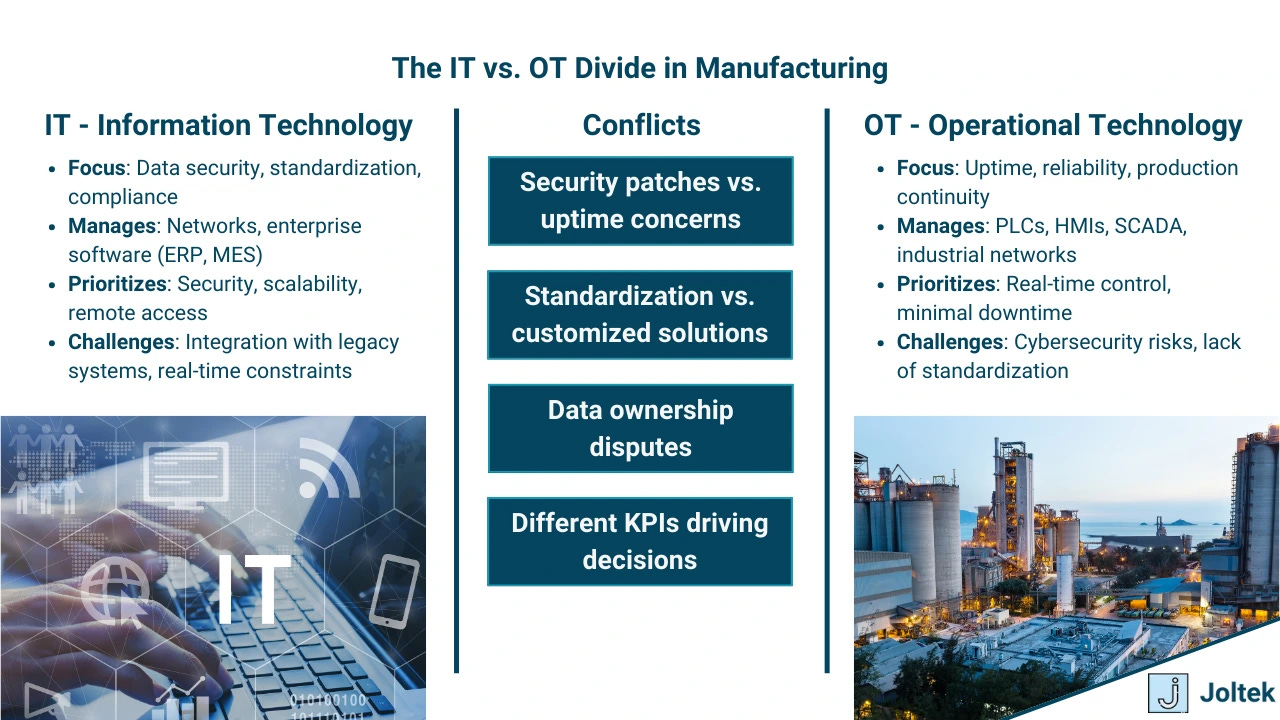

For those unfamiliar, IT (Information Technology) focuses on enterprise systems—network infrastructure, cybersecurity, cloud computing, and business applications like ERP and MES. OT (Operational Technology), on the other hand, is all about keeping production running—PLCs, HMIs, sensors, and the industrial control systems that manage factory operations. While IT ensures data is secure and systems are standardized, OT is laser-focused on uptime, reliability, and ensuring that machines don’t stop. SCADA is a particularly gray area - both parties have a hand at that layer.

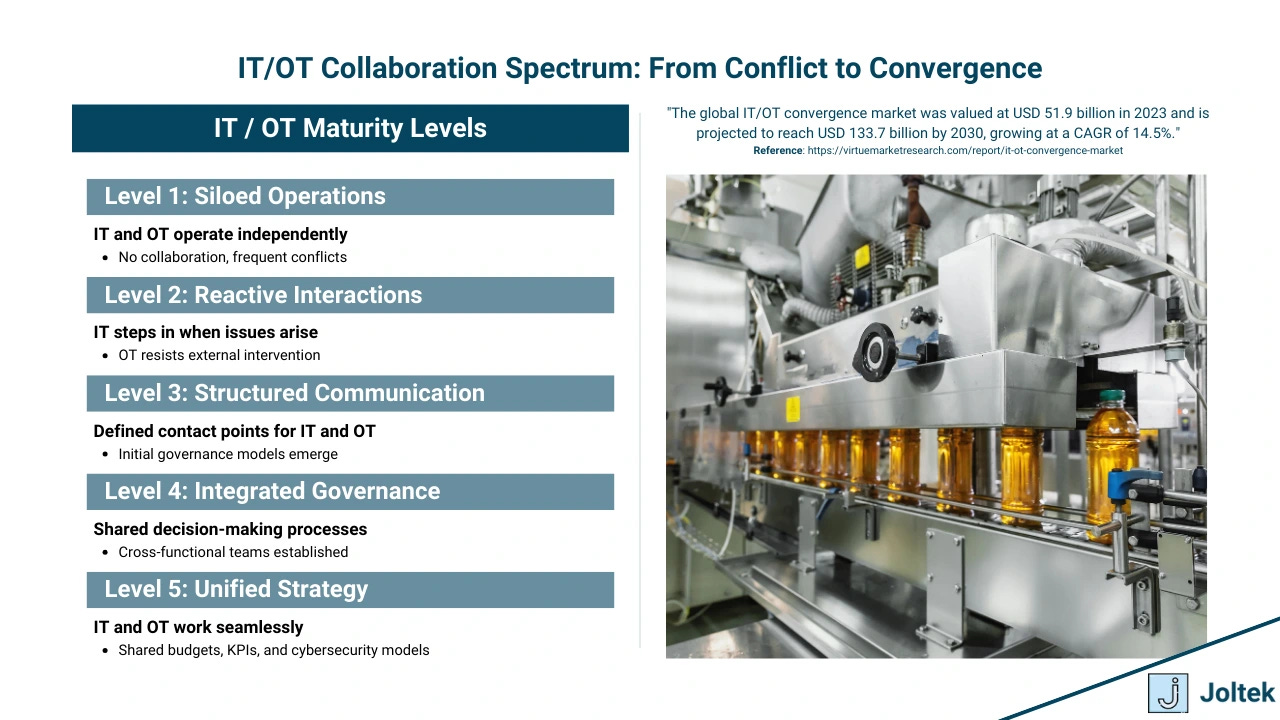

The push for IT/OT convergence has grown as manufacturing becomes more data-driven. Companies want to integrate factory-floor operations with enterprise systems to improve efficiency, predictive maintenance, and supply chain visibility. In theory, this sounds great: Real—time production data feeds into ERP and cloud analytics, helping decision-makers optimize everything from maintenance schedules to inventory levels. But in practice, it’s never that simple.

I’ve seen first-hand how these efforts can go off the rails. IT teams come in with cybersecurity mandates that clash with OT’s need for uninterrupted operations. OT teams push back when IT suggests changes that could introduce downtime or disrupt carefully tuned control systems. And when no clear ownership is defined, projects stall in endless debates about who owns what—who controls the data, who maintains the infrastructure, and who makes the final call on system updates.

In this article, I’ll break down why IT and OT often find themselves at odds, the root causes of these struggles, and—more importantly—what I’ve seen actually work when it comes to bridging the gap. Whether you’re a plant manager, an automation engineer, or an IT leader, understanding these challenges is the first step toward finding a path forward.

My Background

I’ve spent my career (over a decade) at the intersection of manufacturing, automation, and digital transformation. I started out as an electrical engineer, working on factory automation projects right out of school. My early years at Procter & Gamble threw me into the deep end—commissioning production lines, troubleshooting PLCs, and optimizing automation systems. Later, as a maintenance manager at Kraft Heinz, I led a team of 26 technicians and electricians, dealing with the daily realities of keeping operations running.

My transition into consulting and systems integration gave me a broader perspective. Traveling to different plants, I saw firsthand how IT and OT conflicts played out in real-world scenarios. It wasn’t just a technical issue—it was about culture, priorities, and ownership. Getting my MBA helped solidify the business-side view of these challenges, and later, building a SaaS company gave me exposure to how industries outside of manufacturing approach digital transformation. Now, advising manufacturers on IT/OT strategy, I’ve seen what works, what doesn’t, and where companies need to focus if they want to bridge the gap between these two worlds.

Currently, I’m working on a few projects in the space through my consultancy - Joltek.

The IT vs. OT Divide: A Breakdown

If you’ve ever worked in a manufacturing facility, you’ve probably seen the tension between IT and OT firsthand. I’ve experienced it myself—standing on the plant floor in my safety boots, troubleshooting a PLC issue, while an IT manager from corporate calls, asking why a production system isn't complying with a network security policy. The priorities couldn’t be more different between OT and IT.

At its core, IT (Information Technology) is responsible for enterprise networks, cybersecurity, data management, and business applications. IT professionals focus on securing systems, managing access, ensuring data integrity, and maintaining compliance with industry regulations. Their world is structured around standardization, security, and scalability. In contrast, OT (Operational Technology) governs the production environment—automation systems, industrial control networks, and the processes that keep manufacturing running. OT teams prioritize uptime, speed, and reliability, often working with legacy systems that can’t be easily updated or modified without risking downtime.

The best way to explain the divide is with a real example. At one plant I worked with, IT pushed for a routine security patch rollout across all company-managed servers. For office computers, this was a non-issue—install the update, reboot, and move on. But in OT, that same update risked taking down a critical SCADA system, which had been running uninterrupted for months. The OT team refused the update, citing production risks, while IT insisted that leaving an unpatched system exposed the plant to cybersecurity threats. The standoff escalated until upper management had to step in, ultimately delaying the patch indefinitely. The result? IT saw it as a failure in security compliance, while OT viewed it as a win for operational stability.

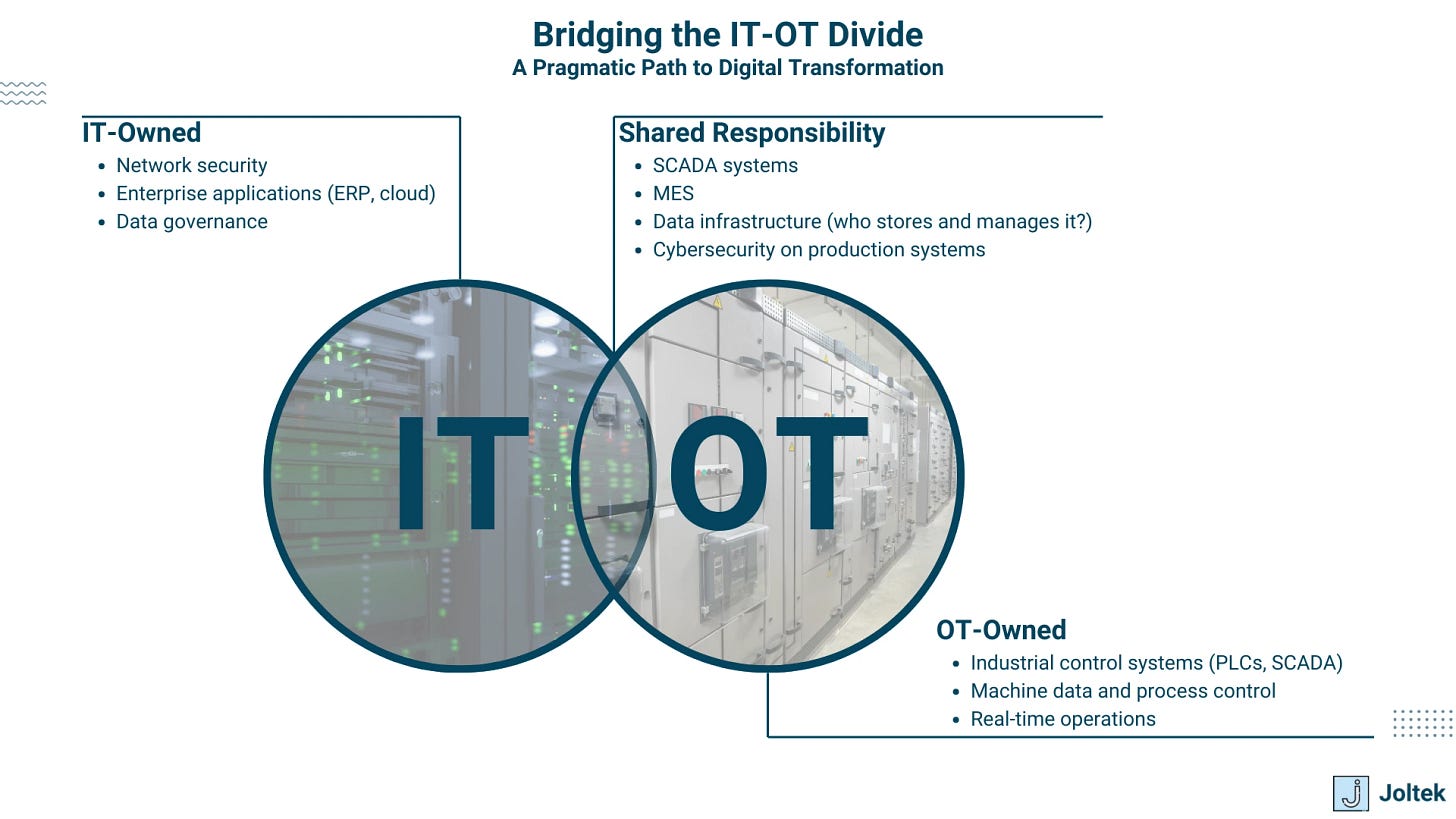

This divide is even more apparent when it comes to who owns what. If a factory needs to store machine data for analytics, should IT manage the servers, or should OT handle the data collection and access? When a production line needs a new MES system, who has the final say—IT, because it touches enterprise software, or OT, because it integrates with automation equipment? These gray areas lead to constant friction and stalled projects.

From my experience, the divide isn’t just about technology—it’s about perspective. IT sees OT as resistant to change and unwilling to modernize, while OT sees IT as disconnected from the realities of the plant floor. Until both sides understand each other’s priorities, the struggle will continue.

Why IT and OT Are in Conflict

If you’ve ever been caught between IT and OT teams in a manufacturing environment, you know the frustration that comes with it. I’ve seen situations where IT implements security policies that lock operators out of critical control systems, and I’ve also seen OT teams run outdated Windows XP machines simply because “it still works.” The divide isn’t just a misunderstanding—it’s a fundamental conflict of priorities, incentives, and even organizational culture.

Technical Conflicts: Different Systems, Different Needs

At the technical level, IT and OT operate in entirely different worlds. IT systems are built for standardization, frequent updates, and strong cybersecurity. They rely on managed networks, centralized control, and redundancy to ensure data security and business continuity. OT systems, on the other hand, prioritize real-time control, deterministic performance, and system longevity. In a production environment, even a few milliseconds of delay can cause major disruptions, which is why OT networks are often isolated and run on specialized protocols like Modbus, PROFINET, or EtherNet/IP—protocols that IT teams typically don’t understand.

Organizational Conflicts: Who Owns What?

Beyond the technology itself, there’s always a struggle over ownership. Who controls the data coming from production equipment? Who manages the network infrastructure in the plant? Who decides which systems get upgraded? These questions rarely have clear answers, and without a defined structure, IT and OT end up in turf wars that stall projects and create inefficiencies.

I’ve seen situations where a plant wanted to implement a new Manufacturing Execution System (MES), but the project stalled for months because IT and OT couldn’t agree on ownership. IT wanted to host the system on corporate-managed servers with strict access controls, while OT wanted local control to ensure real-time access and prevent downtime. Each side had valid concerns, but without alignment, nothing moved forward.

Cultural Conflicts: Different KPIs, Different Mindsets

Even when IT and OT work within the same organization, they measure success differently. IT is typically incentivized by security, compliance, and cost reduction—reducing cybersecurity risks, standardizing systems, and cutting infrastructure costs. OT, on the other hand, is driven by uptime, production efficiency, and safety. If IT enforces a security patch that causes a production stoppage, they see it as a necessary risk reduction, while OT sees it as a failure that impacts their KPIs.

I once worked with an OT team that was fiercely against IT involvement in their control systems. Their reasoning? Every time IT touched something, it introduced downtime, which hurt their OEE (Overall Equipment Effectiveness) numbers. On the flip side, IT saw the OT environment as a wild west of outdated, insecure systems with zero standardization. Both sides were right in their own way, but without shared KPIs, there was no incentive to work together.

The Struggle with Legacy Systems and Modernization

One of the biggest barriers to IT/OT collaboration is the presence of legacy systems in manufacturing. While IT is used to upgrading systems every few years, OT works with industrial control equipment that can run for decades. I’ve seen production lines still running on Windows 98 because upgrading would require costly revalidation, downtime, and retraining. IT teams struggle with this reality—how do you secure and standardize an environment where half the machines are running operating systems that Microsoft stopped supporting 15 years ago?

Modernization efforts often create conflict because they require both sides to compromise. IT wants to push for cybersecurity best practices—patching vulnerabilities, securing networks, and migrating to cloud-based solutions. OT, on the other hand, wants to keep things stable and avoid disrupting processes that have been working reliably for years. Without a clear strategy, these modernization efforts either fail completely or take years to implement.

Why This Conflict Matters

At the end of the day, IT and OT need each other. IT provides the cybersecurity, infrastructure, and data management capabilities that OT lacks. OT provides the deep process knowledge and operational expertise that IT doesn’t have. The companies that figure out how to bridge this gap—aligning priorities, defining clear ownership, and modernizing without disrupting operations—are the ones that will succeed in the digital transformation of manufacturing.

In the next section, we’ll dive into how technology itself plays a role in this divide, and why some manufacturing facilities experience more IT/OT conflict than others based on the tools and architectures they choose.

The Impact of Technology on IT/OT Conflicts

Technology has transformed manufacturing in incredible ways, but it has also amplified the tension between IT and OT. As digitalization efforts ramp up, IT and OT teams are being forced to collaborate more than ever before, but the tools and architectures driving this transformation often highlight the fundamental differences between the two worlds rather than bridging them.

SCADA, MES, and the “Grey Zone” of Ownership

If there’s one area where IT and OT struggle to define responsibilities, it’s in the SCADA (Supervisory Control and Data Acquisition) and MES (Manufacturing Execution System) layers. These systems sit right between IT-managed infrastructure and OT-managed automation, leading to constant debates over who owns what.

SCADA and MES systems are traditionally OT-driven because they require deep process knowledge. OT engineers configure alarms, integrate PLC data, and ensure that the system aligns with production workflows. However, because these systems run on IT-managed hardware (servers, databases, cloud platforms) and increasingly require cybersecurity oversight, IT feels justified in imposing standards and policies on them.

Cybersecurity: IT’s Top Priority, OT’s Biggest Headache

Perhaps the biggest flashpoint between IT and OT is cybersecurity. IT sees cybersecurity as non-negotiable—patching vulnerabilities, enforcing access controls, and monitoring networks for threats are core parts of their job. But in OT, every change to a production system introduces risk.

I once worked with a facility where IT forced a mandatory Windows update on a critical SCADA server running FactoryTalk View SE (Using ThinManager). The update installed without issue—but when the system rebooted, it failed to reconnect to the PLCs, halting production. What seemed like a routine security update to IT turned into a plant shutdown for OT. This reinforced OT’s belief that IT “doesn’t understand manufacturing” and made them even more resistant to future security measures.

On the flip side, OT environments are often shockingly vulnerable from a cybersecurity perspective. Many factories still run outdated operating systems (Windows XP, Windows 98) on their control systems because upgrading would require recertification, retesting, and downtime. IT sees this as an unacceptable risk, while OT sees IT’s proposed solutions as impractical and disruptive.

The truth is, both sides are right. IT can’t ignore cybersecurity risks in OT environments, but OT also can’t afford to adopt IT security policies without considering operational realities. The most successful organizations I’ve seen are the ones that establish cybersecurity policies specifically tailored to OT—balancing security with production reliability.

The Need for a Smarter Approach to IT/OT Integration

Technology isn’t going away—it’s only going to become more integrated into manufacturing. But if IT and OT don’t find a way to work together, these conflicts will only get worse. The key to solving these challenges isn’t just about technology—it’s about governance, communication, and mutual understanding.

Instead of IT dictating security policies without consulting OT, companies need cross-functional teams that include both IT and OT experts when implementing new technologies. Instead of OT resisting every change from IT, they need to work together to find solutions that balance security, efficiency, and operational stability.

In the next section, I’ll dive into who owns what in IT/OT integration efforts and why ownership disputes are one of the biggest blockers to successful digital transformation in manufacturing.

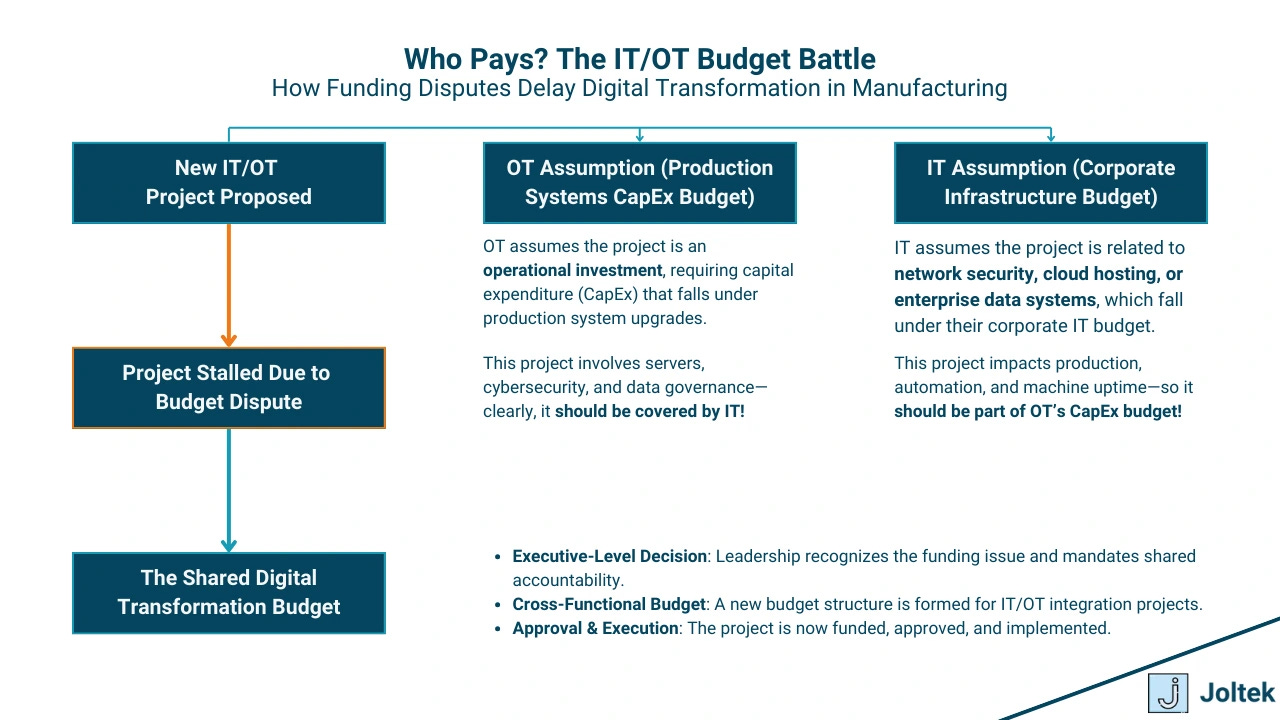

Budget Battles: Who Pays for What?

Even when IT and OT agree on a project, funding can become a roadblock. IT budgets typically come from corporate infrastructure funds, while OT projects are capital expenditures tied to production. This difference in budget structures means that many critical IT/OT projects fall into a gray area, with neither team wanting to take on the cost.

I saw this first-hand when a manufacturer wanted to deploy an industrial cybersecurity solution to monitor network traffic between IT and OT systems. IT argued that since it was a security tool, it should be covered under their budget. OT countered that since the tool touched production systems, it was their responsibility. The end result? No one funded the project, and the security risk remained unresolved.

Companies that have successfully navigated this challenge have done so by:

Creating shared IT/OT budgets for digital transformation initiatives. This prevents either side from unilaterally canceling a project due to lack of funds.

Aligning IT/OT projects with executive business objectives. Instead of framing an upgrade as “IT needs a cybersecurity tool,” it’s positioned as “We need to secure production to avoid unplanned downtime.”

Leveraging external funding sources. Some companies apply for government grants, industry incentives, or corporate-wide innovation budgets to fund IT/OT integration efforts.

One global manufacturer I worked with established a Digital Transformation Board, where both IT and OT leaders met monthly to review proposed projects and allocate shared funds. This governance structure ensured that no single department had veto power, and projects were evaluated based on business impact rather than departmental preferences.

How to Prevent IT/OT Ownership Disputes

Ownership and budget battles won’t disappear overnight, but companies can take proactive steps to minimize them:

Clearly define ownership boundaries at the start of any new IT/OT initiative.

Establish cross-functional governance teams to oversee shared systems.

Ensure both IT and OT have input in funding decisions for digital transformation projects.

Use hybrid models where possible, allowing IT to manage security and infrastructure while OT retains control over real-time operations.

At the end of the day, IT and OT both want the same thing—a more efficient, secure, and productive manufacturing environment. The companies that recognize this and establish collaborative ownership models will be the ones that move beyond internal conflicts and actually succeed in their digital transformation efforts.

Solutions and Best Practices: Aligning IT and OT

Successfully integrating IT and OT requires clear leadership, practical training, and modern architectures that balance security with operational needs. Companies that get this right don’t force IT policies onto the plant floor or allow OT to operate in isolation. Instead, they establish governance, training, and technology frameworks that encourage collaboration while maintaining reliability.

Leadership: Defining Clear Ownership

One of the biggest reasons IT/OT projects fail is a lack of defined ownership. Successful companies appoint a dedicated IT/OT integration leader or create a joint governance team that includes decision-makers from both sides. This helps prevent unnecessary conflicts over system control, cybersecurity policies, and infrastructure changes. Some companies implement shared KPIs, ensuring IT’s security priorities align with OT’s need for uptime and efficiency.

Training: Building a Common Language

Misunderstandings between IT and OT teams often create unnecessary resistance. The best way to bridge this gap is through cross-training programs. IT teams should learn about industrial automation, PLCs, and real-time control, while OT teams should gain knowledge in network security, data management, and IT best practices. Some companies take this a step further by implementing job shadowing programs, where IT personnel spend time on the plant floor, and OT staff sit in IT meetings to improve mutual understanding.

Technology: Reducing Friction

A well-designed infrastructure can prevent many IT/OT conflicts. Zero Trust Security allows IT to enforce cybersecurity policies without locking down critical production systems. Edge computing reduces reliance on cloud-based data processing, ensuring OT teams retain control over real-time decision-making while still allowing IT access to essential production data. These approaches help IT maintain security without disrupting OT’s operations.

Bringing in External Expertise

Many companies bring in third-party consultants with IT/OT expertise to navigate these challenges. External advisors can facilitate discussions, establish governance models, and recommend security frameworks that balance IT’s need for control with OT’s need for reliability. A neutral third party can often help resolve disputes that internal teams struggle to settle on their own.

Final Thoughts

IT and OT will never fully merge, but they can work together effectively. Companies that invest in clear leadership, cross-team training, and well-designed architectures will see fewer conflicts and faster digital transformation, ensuring both security and operational efficiency.

The Automation Navigator is brought to you by Sean Dotson and Automation AMA, a company founded and run by an industry leader in assembly, robotics and packaging. Automation AMA offers a variety of services to help you on your automation journey or to help fine tune your engineering, sales, operations and business development departments. Learn more at www.automationAMA.com or shoot me an introductory email.