Manufacturing Automation – All in Costs

The true costs and ROI calculations for automation investments

This week we have a special guest author. Chris Stergiou was kind enough to write some articles that we think our Automation Navigator audience might find interesting. Look for more of Chris’ work in the future.

Return on Investment

The formula for ROI is typically written as:

ROI = (Net Profit / Cost of Investment) x 100

In project management, the formula is written similarly, but with slightly different terms:

ROI = [(Financial Value - Project Cost) / Project Cost] x 100

As the Net Profit or Financial Value, are speculative as they project into an Uncertain Future, for Manufacturing Automation projects one might assume that the Cost of Investment or Project Cost would be “easy” and “knowable” upfront so as to provide some measure of control if not comfort.

Generally this is NOT the case and here’s why

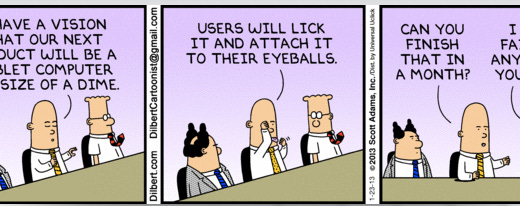

First, as a creative process, “there many ways to skin the cat”, and while each approach offers unique advantages, simultaneously, incremental unforeseen costs quickly pile up as the unique advantage in the method may be in some second or third order attribute which, while nice to have, doesn’t add corresponding value to the first order objective.

While more difficult to quantify upfront, simply knowing this dynamic means that we can mitigate the impact by focusing on the Why? for the automation to begin with and simulating various approaches on a comparative basis, while leveraging the unique Domain knowledge already functioning in our Process.

Second, and related to the first, “the shiny object syndrome”, driven by technology FOMO and industry Hype, invariably creeps in as Scalability, Flexibility and Sustainability are used as vague hedges pretending to foretell the future, as if that was possible and most important, as if those that bequeathed our Current State Process were either remiss or negligent in designing it!

Usually embodied in “general purpose” solutions, invariably a bulk of the costs are tied into features and functionality that will never be used in the our Specific and Unique application, making the features themselves a cost burden and leaving less funding available for required functionality that must now be custom developed or appended with yet another “general purpose” layer, compounding the costs.

Third, like the second, “keeping up with the joneses”, in a parody of industry ”best practices”, turning the concept of automation serving as a competitive advantage on its head by taking our already unique and distinct advantage in manufacturing our product, and harmonizing that process into a commodity spiral of everyone having the same “advantage”.

Great approach of course IF our objective is to serve as the development ground for 3rd party Integrators and Solutions Providers to perfect their offerings but for Competitive Advantage, Not so Much! And even worse, since our ROI calculation was based on reaping some of the benefits of that competitive advantage, it’s unlikely we will meet our projections!

Finally, amplifying the costs is a background Scope Creep, no matter how much we try to avoid it as a negative feedback loop to costs is created by incremental “benefits and functionality” coincidentally aligned with general purpose “features” or functionality, urging ROI justification, when it simply doesn’t exist in the problem at hand, BUT it does feel like we’re getting a freebie.

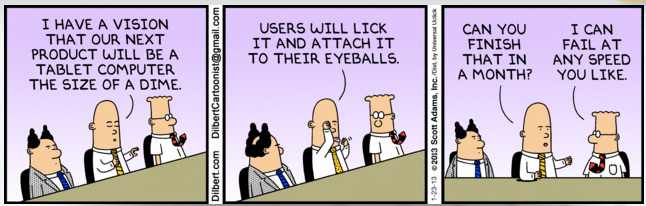

Add in execution challenges compounding this; Engineering Change Orders, Human Project management and the ROI goes out the window, pretty quickly … but we only used the calculation to get approval, and the unlikely post-mortem confirmation, will have justifications for all cost overruns, as if they came “out of the blue” and were beyond our control.

A Better Way

Primarily an integration process, the design of Automation relies on the innovation and creativity applied to a defined manufacturing process. The engineering involved is interdisciplinary, systems oriented and ONLY succeeds when it solves a specific problem with the local economics of the process, as expressed through the ROI.

Understanding that the objective of the automation is Meeting the ROI; engineer the solution to the ROI upfront without preconceptions, faulty assumptions or technological ideology masquerading as preparing for an Uncertain Future.

At any point in time, a step in the process or the entire process are ripe for right sized Automation, meeting or exceeding the ROI along some continuum of functionality vs. costs.

And quite often a key tip-off that this opportunity is waiting to be exploited is the remark:

“We tried automation for this application but couldn’t meet the ROI.”

Chris Stergiou is an experienced electro-mechanical systems engineer providing custom design and build services to R&D and Manufacturing Clients on an outsourced, project basis or working remote with your in-house team.

With a progressive 30 year, multi-industry experience, provide manufacturing automation equipment and custom manufacturing tooling and methods. I bring significant value anywhere along the automation continuum ranging from "Blank sheet of paper", Strategic Assessment of Automation plans and Concept development, System Architecture Design, Detail Design and Build.

Reach out to have a conversation regarding your automation requirements and how I can Add Value to your automation strategy and project.

The Automation Navigator is brought to you by Automation AMA, a company founded and run by an industry leader in assembly, robotics and packaging. Automation AMA offers a variety of services to help you on your automation journey or to help fine tune your engineering, sales, operations and business development departments. Learn more at www.automationAMA.com or shoot me an introductory email.