Make vs Buy Decisions in Machinery Design

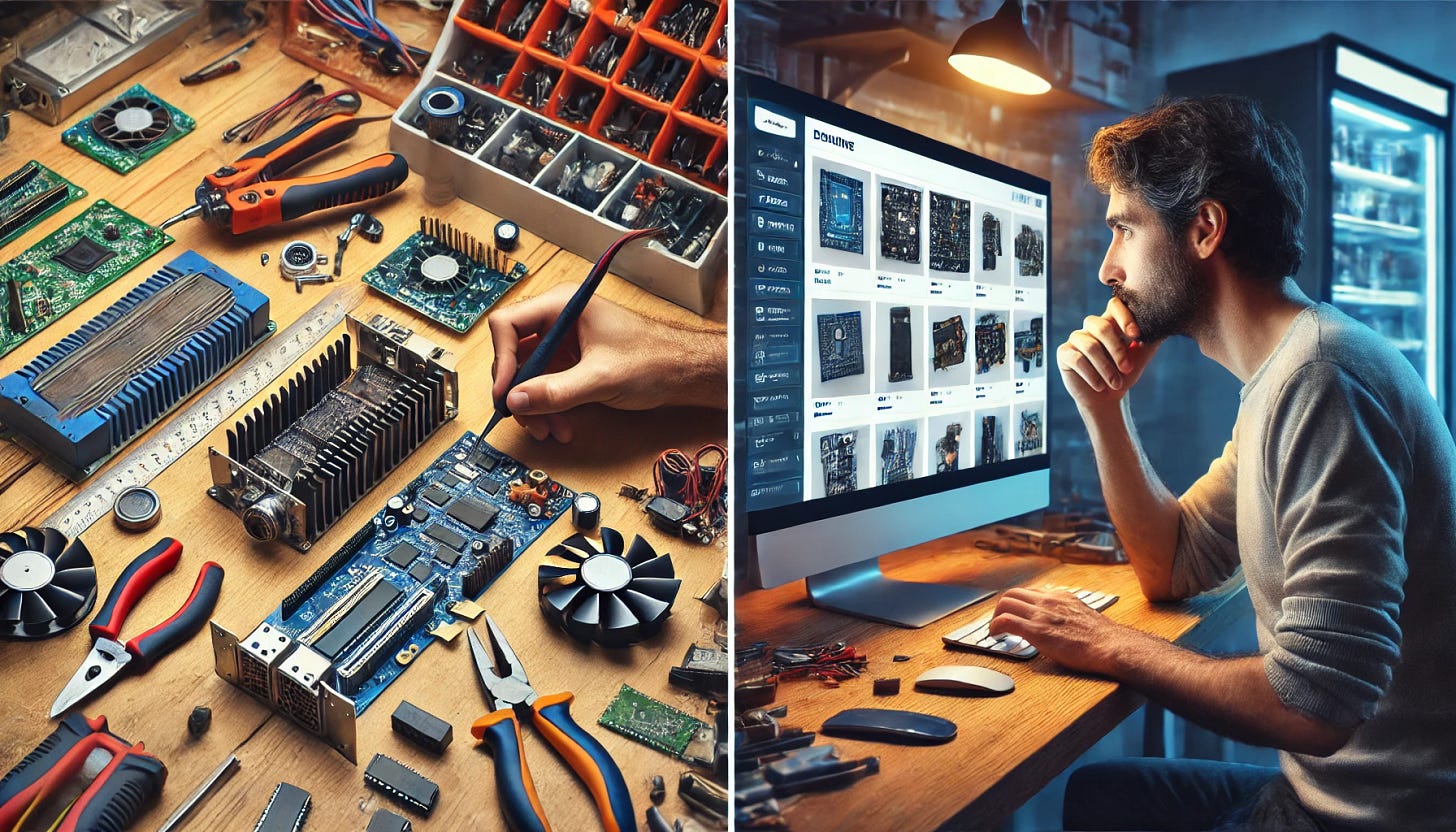

Is it better to reinvent the wheel, or just fire up your browser?

What are Considerations in Make vs Buy Decisions

Every design engineer has been there, sitting in front of a CAD station or whiteboard, sketching out a design and wondering, “Do I design this part from scratch or do I just buy it off the shelf?” The answers are not always simple, but here are some things to consider when making these decisions.

The beauty of Mechanisms

There is nothing more elegant than a complex mechanism that turns one direction of motion (linear or rotary) into another. We’ve all seen complex 4-bar mechanisms that create amazing cam-like motion paths using nothing more than a simple motor or linear actuator. In fact, I had this book on my shelf for many years, and as a young engineer, I’d often refer to it for inspiration.

507 Mechanical Movements - Henry T. Brown

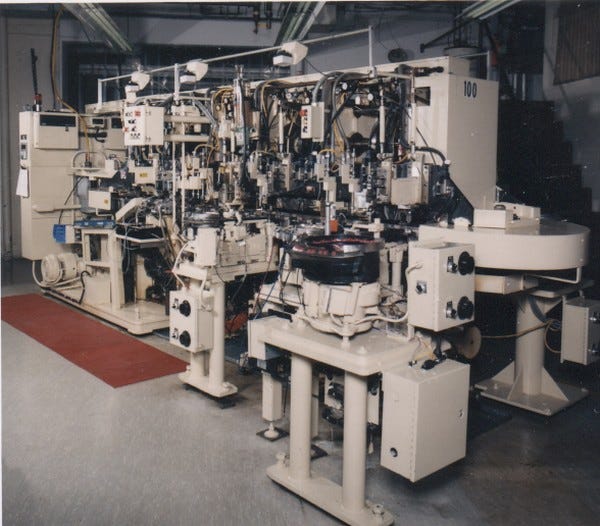

I think nothing illustrates this better than the classic line-shafted machines made popular by Bodine in the 1970s and 80s. Using one motor with a series of cams and linkages along the shaft, they were able to create fully automated multi-station assembly machines. They were nothing short of works of art. It took a lot of engineering and calculations to get the cam profiles and linkage lengths right, but once it was dialed in, it produced parts like a champ. Some of the first machines I helped design used this same concept (albeit in a rotary format versus linear).

But Will It Work?

As stated, once it’s dialed in, the machines worked. However, it took a lot of trial and error and calculations to get them to this point. Once the design had been standardized, they could make adjustments to strokes and dwell times relatively easily (they still had to remake cams, but they knew how to do that).

The issue with a new design is that you don’t have the tribal or previous knowledge. When I coach younger engineers about designing mechanisms, I have three basic tenets:

It won’t work the first time (there are always exceptions, but 99% of the time it has to be tweaked).

It might work the second time, but you don’t know for how long. It might be fine for a month, then implode on itself due to excessive loads, bearing failure, etc.

Only on the third try and after life cycle testing do you have a design in which you can feel confident.

Granted, there are always exceptions, but I’ve found these, in my experience, to be pretty true. So, if you’re making a one-off design, you might need to consider that you won’t get it right the first time. This is where the make-vs-buy decision begins.

A Make vs Buy Example

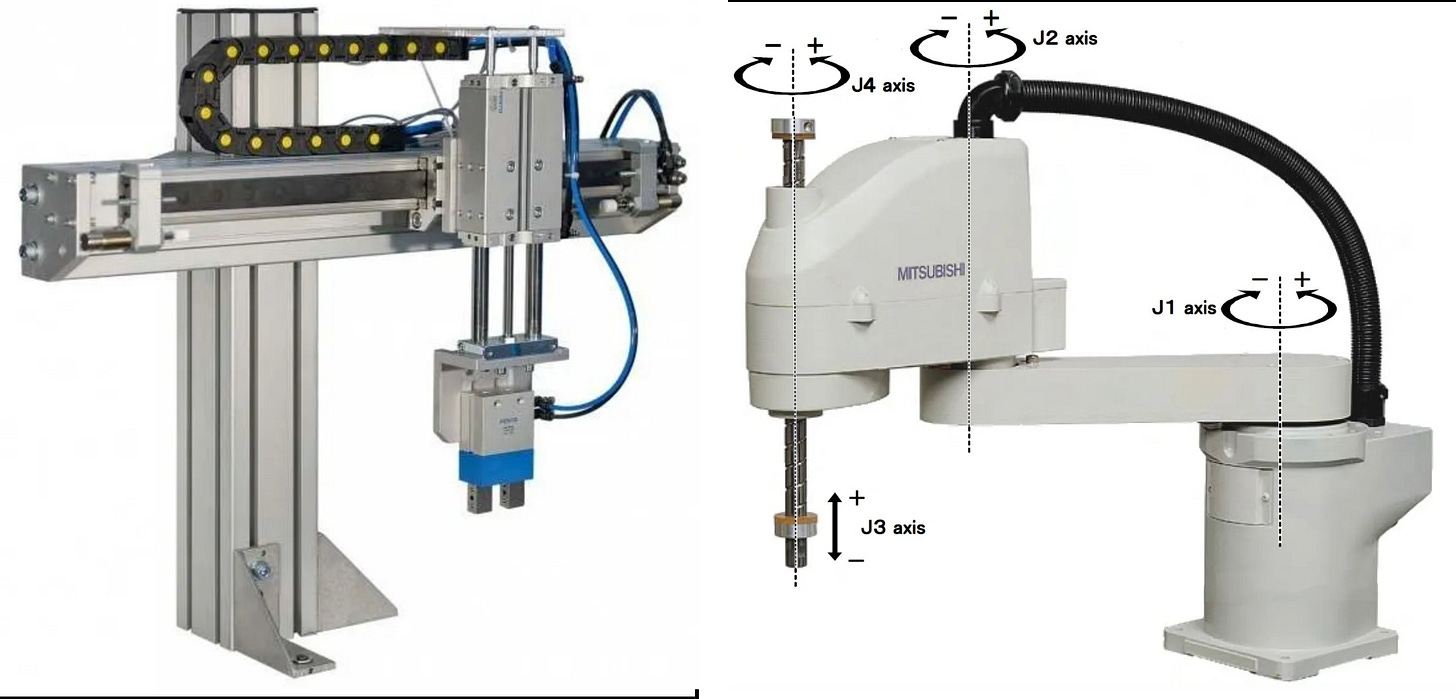

Let’s look at one of the simpler make-vs-buy decisions that all machine designers have faced: the simple pick and place. In our example, we will compare the tried and true pneumatic pick and place with a SCARA robot (yes, they do make 2-axis robots, but SCARAs are far more common and provide extra benefits, as we shall see later).

So your objective is to pick an item from position A and deliver it to position B. For the purposes of this comparison, I will ignore the EOAT or gripper as it would be the same for both applications.

In the case of the pneumatic pick and place, you will have:

2 pneumatic cylinders

4 flow controls

4 lengths of tubing

2 solenoid valves (3rd for the gripper, but we’re ignoring that)

4 SS or Hall effect sensors for cylinder position

Cable management of some sort

At least 2, if not 3 or 4, custom-designed and machined parts to connect the axes together

4-6 (depends) rungs of ladder logic to control the motion

In the case of the SCARA robot, you will have:

1 robot

One line of code to move from position A to position B (yes, I realize there is more to the robot program, just as there is more to the PLC program, but we’re talking about just the motion command itself)

“But Sean, the cylinders are cheap compared to the robot.” Well, dear reader, on the surface that appears to be correct. However, when you dig in a bit deeper, there are hidden costs beyond the initial material outlay that come into account.

Hidden Costs of Design

So yes, the cylinders are relatively cheap, as are the sensors, flow controls, tubing, etc. However, think about the other cost that most engineers and firms tend to ignore: Time.

Again, ignoring the EOAT, which will be the same for both applications, and assuming you already know which cylinder and sensor you want to use, consider the following:

You need to design the interface plates, detail them, and get quotes from local or internal machine shops.

For procurement, you need to write POs for each of these items (probably not all coming from the same supplier).

Each item has to be received and entered into inventory.

At assembly, you need to bolt all of these things together, wire in the sensors, cut tubing, and install the flow controls.

Install solenoids and plumb to the solenoid valves.

Adjust the flow controls, adjust the sensors, and then test the logic.

For the robot, you write one PO, receive one item, bolt the robot to the tabletop, write some simple code, and it’s moving. Furthermore, most SCARAs have internal cable and pneumatic routing, and many offer solenoids built in.

And while I’m not one to promote releasing a desing before you’re sure it’ll work, there is a big advantage knowing that as long as the points are within the robots’s envelope you don’t need to be worried about EXACT placement of the robot and pick and place posiitons.

Hidden Costs of Maintenance

Now that the assemblies are mounted into the machine, you begin to run it. You notice that position A, from where you are picking, is not exactly aligned to where you “thought” it might be. The same goes for the drop-off at position B. Or, heaven forbid, the feeder bowl you ordered 6 weeks ago comes in a few millimeters shorter than you expected. Now you're making new parts or ordering new cylinders.

It's also moving a bit faster than you want. Now you spend time loosening bolts, slightly adjusting the pick and place position. You play with the flow controls to try to get a balance of “fast enough but not too fast.” The sensors and end stops need to be adjusted based on the final positions.

Meanwhile, the robot programmer adjusts two of their pick points and speeds via a keyboard. Done.

Fast forward to the machine in the field, and we all know where this is going. You get a call from the operator or maintenance person saying that the pick and place is no longer aligned or that it’s moving too fast and dropping parts. “Did you adjust anything physical?” you ask. “No, of course not.”

A long phone call or a service trip later, you discover that, lo and behold, they did try to adjust the station and controls.

Reliability & Flexibility

Considering that SCARA robots are now in the $7-10k price range, the argument against using them is becoming more and more difficult to justify. Add in the flexibility to adapt to changing parts or designs, as well as the ability to repurpose them on future equipment, and it becomes a tough sell to stick with traditional “design it yourself” methods.

And we haven’t even discussed reliability. At every cylinder, sensor, and flow control, there is an additional possible point of failure. With robots now achieving thousands and tens of thousands of hours of MTBF (Mean Time Between Failure), they are essentially bulletproof.

Other Make vs Buy Examples

While the example above is simply one (and it does not apply to every situation), there are many other make vs buy options to consider. While it might be a bit more expensive to buy a part vs make it yourself, when you factor in lead times, chances of mistakes, design time, etc., the gap closes considerably. Other examples of make vs buy decisions to consider:

Designing parts and sending them to machine shops vs using companies like Misumi (or even McMaster for simple standoffs, etc.) that can provide customized machined components.

Using potted premade I/O cables vs field serviceable ones. I know there are a lot of factors to consider here, but I see a lot of builders using field serviceable connectors just so they don’t have to stock premade cables of different lengths. It’s just another point of failure and additional time to wire.

More complex assemblies, such as placing O-rings onto parts. While you can design a system with a feeder bowl, escapement, an O-ring gripper, and pick and place, you could also go to a company that specializes in O-ring installation machinery and integrate this. They’ve been doing it a lot longer than you have. While more expensive, all it takes is a couple of service calls to eat up any savings you might have seen.

Conclusion

One must weigh more than the cost of the hardware when determining if you will make vs buy the components for your machinery. Factors such as flexibility, cost and ease of maintenance, longevity, and lead time to market are all costs that need to be considered in these decisions. Every situation is unique, but you should always perform this exercise at the most basic level before deciding to design something unique and novel. Why reinvent the wheel?

The Automation Navigator is brought to you by Automation AMA, a company founded and run by an industry leader in assembly, robotics and packaging. Automation AMA offers a variety of services to help you on your automation journey or to help fine tune your engineering, sales, operations and business development departments. Learn more at www.automationAMA.com or shoot me an introductory email.

Thanks Sean, this was an enjoyable read and very reflective of what we go through every day