10 Principles of Good Design

How rules invented by an industrial designer apply to automation and robotics

Industrial Design vs Industrial Machine Design

Let me first clarify a few terms that are often misunderstood. Industrial design refers to the professional practice of designing products, devices, objects, and services that we use daily, such as laptops, radios, shavers, speakers, and TV remotes etc.. Industrial designers are responsible for creating these innovative and useful products.

This is quite different from industrial machine design, which focuses on designing the machines, systems, and processes that manufacture the products conceived by industrial designers.

While these are distinct professions, they are deeply interconnected. Product designers should always consider the designers responsible for automating the production of their designs. At a minimum, they need to create products that can be manufactured through automation, even if not easily.

The Father of Industrial Design (not me)

My son is currently pursuing his Master’s in Branding and Art Direction at VCU. I’ve often thought that if I had more of an artistic streak, I might have become an industrial designer myself. Instead, I gravitated towards machine design, where prismatic shapes—rectangles, cylinders, and the like—make more sense to me than “swoopy” or organic forms.

Throughout his undergraduate studies and even more now in grad school, my son and I have exchanged videos and messages on design, UI, and product development. In one of our discussions, he introduced me to Dieter Rams, who is widely regarded as the father of modern industrial design. Many iconic and influential products were either designed by Rams, one of his students, or shaped by his design philosophy. Apple’s designs, in particular, owe a great deal to Rams’ influence. Jony Ive, although he may not openly admit it, was clearly inspired by Rams’ work.

The 10 Principles of Good Design

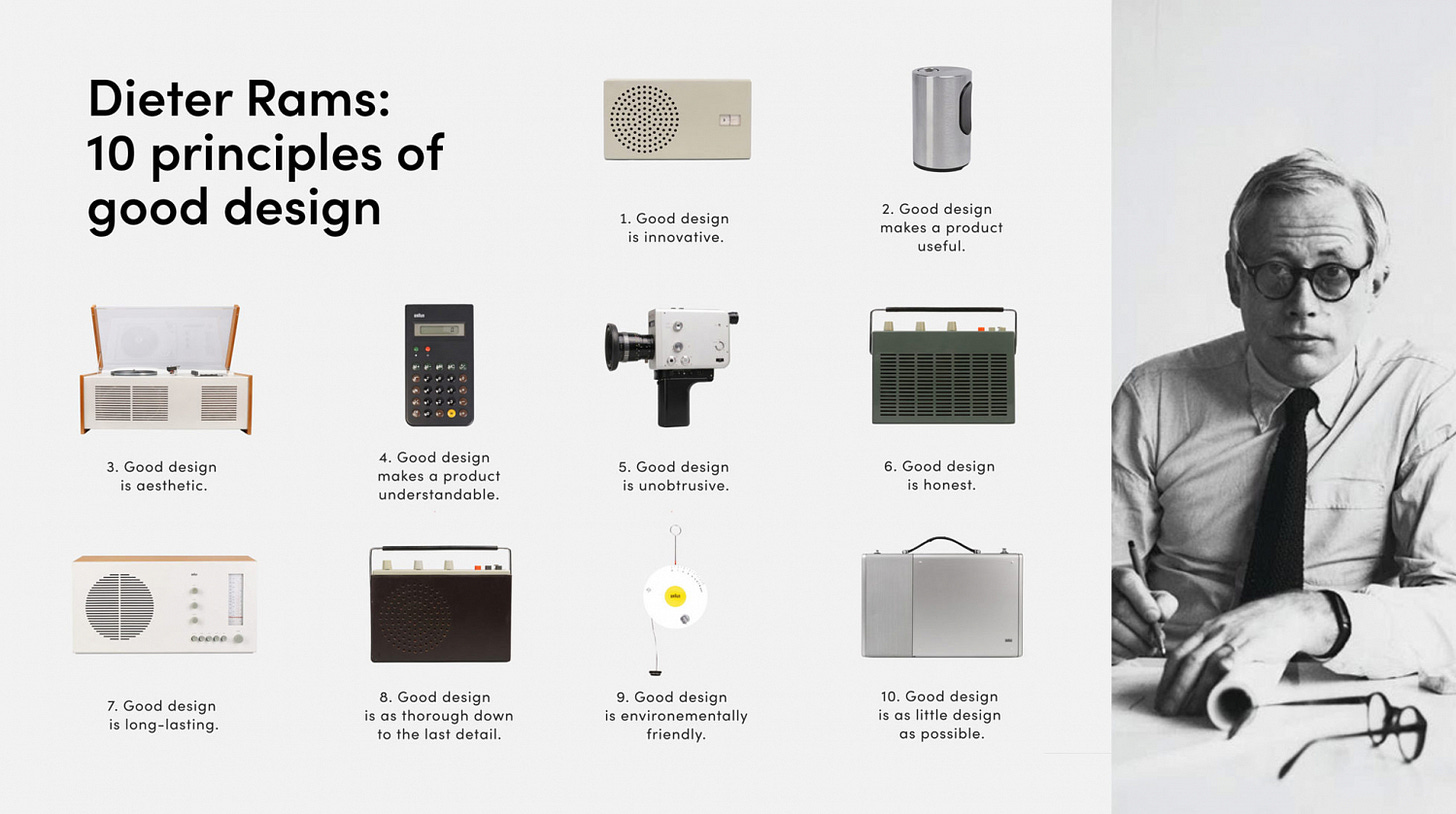

One of Rams’ key contributions to product design is his “10 Principles of Good Design.” These principles have been extensively discussed in articles and analyses regarding their relevance to design. I won’t rehash those discussions here, but I highly encourage you to explore these principles and how they apply to product design.

In short his principles were that good design:

Is innovative

Makes a product useful

Is aesthetic

Makes a product understandable

Is unobtrusive

Is honest

Is long-lasting

Is thorough down to the last detail

Is environmentally friendly

Involves as little design as possible

So How Do these Apply to Automation & Robotics?

Let’s take each of Rams’ principles and see how they apply to automation and machine design.

1. Is Innovative: This principle is straightforward. Nearly all automation projects involve some level of problem-solving. Even with standardized products, there is often a degree of customization where innovation and creativity are essential. If these challenges were simple to resolve, manufacturers wouldn’t require the expertise of integrators and machine builders.

2. Makes a Product Useful: This principle is equally straightforward. An automation system or robotic cell must be useful, addressing a problem significant enough to justify its cost. In my experience, I’ve rarely encountered an “unnecessary” automation system. More often, the challenge lies in convincing manufacturers to invest in a necessary system.

3. Is Aesthetic: This is where opinions may differ. Some argue that a system only needs to be functional and meet its stated goals. While that’s fundamentally true, I believe that a truly good design should also be aesthetically pleasing. This doesn’t just mean being clean, tidy, and organized—it also involves being ergonomic, with an intuitive HMI (human-machine interface) that is easy to navigate and understand.

In my experience, many machine builders overlook aesthetics. While their systems may function well, operators often find them unpleasant to work with. It’s like choosing between a Honda or Toyota, which will get you from point A to point B, and a Mercedes, BMW, or Porsche, which elevates the experience.

4. Makes a Product Understandable: Many may interpret this principle as ensuring that the HMI is easy to use, which is indeed essential for good design. A great user interface is one that doesn’t require extensive training or instruction to operate—think of devices like the iPhone or an Android device.

This principle also extends to the underlying code of our systems. Too often, while the code may function correctly, it is uncommented, difficult to follow, and, quite frankly, unattractive. I believe that good code should not only be functional but also easy to read and aesthetically pleasing. Currently, I’m working on a project where we are rewriting functional yet overly complicated code.

We must also consider the mechanical design and layout of the system. This involves making adjustment points easy to identify, using tool-less hardware, applying labels and decals, and ensuring that components meant to remain fixed are difficult to adjust (e.g., tamper-proof fasteners, hidden fasteners, pinned parts). In a perfect world, operators would require no training to use the system. While we know this is nearly impossible, it is a worthy goal for which to strive.

5. Is Unobtrusive: I’ll be honest—finding a direct correlation for this principle was a challenge. The best comparison I can draw is that good machine design does not necessitate radical changes to a business’s existing processes. While we have all designed machinery that enhances procedures, it is often better received when it complements current operations.

Radically altering a customer’s business model can be transformative, but it requires a unique client willing to embrace such changes. In contrast, augmenting existing processes rather than overhauling them is almost always more welcomed.

6. Is Honest: Here, I need to refer to what Rams intended by this principle. He explains that “it does not make a product more innovative, powerful, or valuable than it truly is. It does not attempt to manipulate the consumer with promises that cannot be kept.” This is especially important in automation.

Far too often, automation providers overpromise and underdeliver. How many times have you heard of a system that was quoted to run at X products per minute or maintain Y uptime, only to struggle to meet those metrics during the FAT? When a customer requests unrealistic metrics—whether in rate, uptime, rejects, or even delivery lead times—it’s crucial to be transparent about what your design can realistically achieve. Overpromising not only damages your reputation and company but also undermines future automation projects for that customer. Once they’ve been burned, they’re far less likely to take a risk on automation again.

7. Is Long Lasting: No one wants a system that breaks down right after the warranty expires. I’m particularly proud of having built systems that are still producing parts after more than 20 years. Some might say we built them “too well” and that they’ll never need replacing, but I see it differently. Quality and longevity earn far more respect and repeat business from a customer than a machine that needs replacing after just five years.

8. Is Thorough Down to the Last Detail: Don’t cut corners on the details. It’s the hidden elements that distinguish good machine builders from great ones. Anyone can shove wires under a frame and call it done, and yes, it may function. But what sets you apart is the extra attention—routing wires neatly in trays, labeling pneumatic connections, and placing placards inside enclosures. These small touches elevate your work. While your customer might not express their appreciation directly, when they compare your designs to others, they’ll recognize the value you bring.

9. Is Environmentally Friendly: This principle can be more challenging to quantify since we aren’t producing millions of widgets. However, various aspects of machine design significantly impact the environment. For instance, we know that compressed air incurs high costs in terms of electricity due to inefficiencies. Many companies, like Toyota, have begun to mandate minimal use of compressed air in their machines, reserving it only for absolute necessities.

Once rare, machines that operate without compressed air are now available on the market. Additionally, minimizing electrical draw in other ways can further reduce environmental impact. Even considerations such as the amount of metal used in frames and tabletops can contribute to a more sustainable design.

10. Involves as Little Design as Possible:

This principle is perhaps my favorite and one I have championed and taught for many years. In fact, I wrote an entire article on this very subject. I am a strong advocate for using proven, off-the-shelf concepts in automation. While novel and unique mechanisms or complex custom designs may seem appealing, they often involve more design work than necessary. Many of these problems have already been solved using established techniques and products. In short, embrace the K.I.S.S. principle: Keep It Simple, Stupid.

Conclusion

While industrial design and automation/machine design are distinct disciplines, I believe that Rams’ principles of good design can be applied to both. Too often, machine designers focus solely on the final outcome of the system, overlooking the inputs that drive it. By incorporating these design principles earlier in the process, we, as machine designers, can enhance the value of our designs and, ultimately, elevate the profession as a whole.

The Automation Navigator is brought to you by Automation AMA, a company founded and run by an industry leader in assembly, robotics and packaging. Automation AMA offers a variety of services to help you on your automation journey or to help fine tune your engineering, sales, operations and business development departments. Learn more at www.automationAMA.com or shoot me an introductory email.

Excellent article Sir!